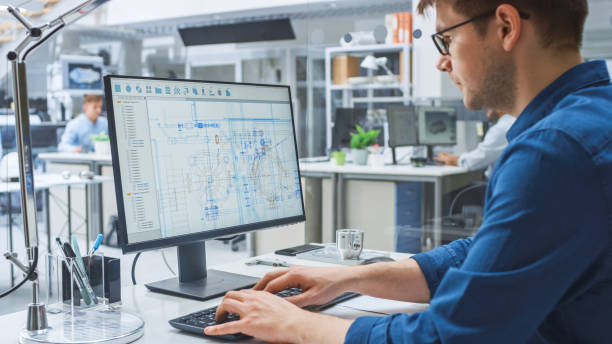

Processes of measurement, testing, and continuous monitoring—especially when working near or under high voltage—are rarely automated or processed using modern software approaches such as artificial intelligence, GIS visualization, Cloud, or IIoT. Additionally

Expert diagnostics is the most important component of the condition-based maintenance concept. Through high-quality and precise analysis of test results, measurements, or continuous monitoring, it is possible to diagnose the actual condition of the equipment as

well as the type of fault.

Condition Based Maintenance (CBM) is used to diagnose changes in the condition and/or performance of monitored devices, equipment, and systems, which serves as the primary trigger for maintenance activities. The optimal timing for performing maintenance is determined based on real-time monitoring of the actual condition of the equipment.

Failures and breakdowns of vital power equipment can lead to power outages in parts of the power system, significant financial losses, and have a major impact on the operation and stability of the electrical grid. The importance of the reliable operation of vital power equipment increases year by year, in parallel with the growth of electricity generation, transmission, distribution, and consumption.

Whether you have a question, need technical support, or want to learn more about our services — we’d love to hear from you. Reach out today and let’s start the conversation.

Dedicated to revolutionizing the electrical industry through cutting-edge technology, expertise, and a commitment to system reliability and safety.